The factory is set up in a picturesque 30 acres plot amid thick green Rubber Plantation. The processing capacity of the plant is 1000 Barrels (200 metric tons) of field latex per day. The Company procures field latex from the farmers fields throughout the length and breadth of Kerala State. SMR Plantations owns and operates a big fleet of transport vehicles for supply of empty barrels fed with anticoagulant to the farmers and collection of field latex filled barrels from the plantations. The farmers are offered the best possible farm gate price for their product due to the efficient management of procurement, processing and sale by SMR Plantations.

Latex Factory

The Company initially started its operation with a single latex separator machine. Through a well planned activities and operations company achieved prime position in number of latex separators in its most modern plant now, and subsequently gained a considerable production capacity through a phased manner during these years.

For achieving value addition in the process, we have started a Skim Crepe Unit in the initial year and quality crepe is exported and sold domestically. Subsequently, in view of further value addition in Crepe Processing, we have commissioned a new plant for converting Skim Crepe to Skim Block, which is generating high demand from both domestic and international markets and we are exporting the same too.

The most modern plant of the company was commissioned in the year 2003. The Centrifuged machines were procured from M/s. Alfa Laval, regarded as the best centrifuging machine manufacturers in the world and their machines are used worldwide. Now we have enough machinery in operation and another lot is planned to be commissioned in the future.

While using these machines, the efficiency rate achievable in the production process is very high on comparison with other machines in the field. Due to this efficiency advantage, we could offer our product with competitive rates to our customers.

Manufacturing Process

Collected field latex is unloaded from the barrels into the primary storage tank. Required chemicals are added into the collected field latex for separating the clay content of sludge from the latex in the mixing tank. Sludge is to be removed from the latex for facilitating the latex separator machine to work efficiently. Sludge free latex will be passed through the latex Separator machine having a bowl with 166 plates with an RPM of 7000. The latex will be passed through the rota ng plates so as to separate the water content from the latex. The separated water will be driven into a storage tank where more chemicals will be added in the finished product tank and subsequently filled either in the barrels or flex bags for stuffing into containers for disposal.

End Products

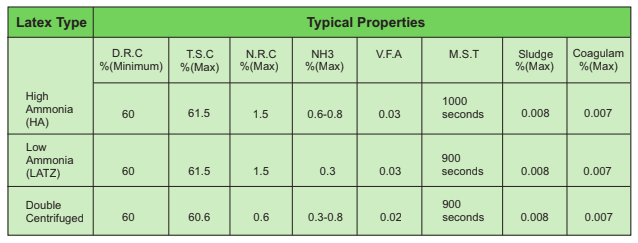

Natural Rubber Centrifuged Latex 60% DRC (HA & LATZ) and Double Centrifuged Latex

Packing

- Barrels – 200Kgs net

- Flexi Bags (only for export) 22000Kgs with 5% plus or minus tolerance.

End Use

- Gloves

- Condoms

- Balloons

- Adhesives

- Foams

- Carpet Backing

Bye Product- Skim Crepe Rubber

End Use

- Low Grade Rubber Products